English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

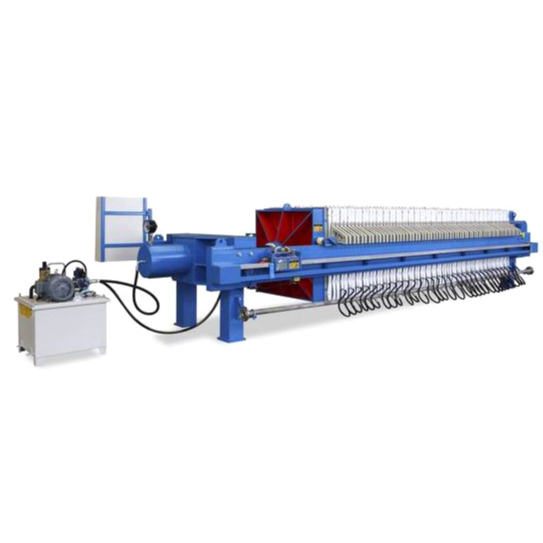

Filter Pencet

Minangka pabrik pers saringan kualitas tinggi profesional, sampeyan bisa yakin tuku pers saringan saka pabrik kita lan kita bakal menehi layanan sawise-sale paling apik lan pangiriman pas wektune. Muga-muga bisa nggawe hubungan kerja sama sing ramah karo perusahaan sampeyan kanthi produk sing berkualitas tinggi, rega sing cukup, layanan sing wicaksana lan nggawe tangan sing luwih apik ing mangsa ngarep.

- View as

Polimer Elastomer Diaphragm Filter Press

Diaphragm filter press is a kind of filter press installed between the filter plate and the filter cloth with diaphragm equipment, as an important feature of the filter press accessories, its diaphragm due to the model, type of its diaphragm accessories material is also different, rubber diaphragm and polymer diaphragm Generally speaking, from the general category, diaphragm filter press diaphragm classification mainly includes polymer elastomer diaphragm and rubber diaphragm, which is the product of the current development in the past ten years, in the past materials are also different, as a rubber diaphragm, Rubber we all know its properties, in different types of rubber for different substances have different characteristics, usually rubber diaphragm filter press rubber diaphragm is mainly for weak alkali and weak acid filter materials will be more used, but can not be used for organic solvent filter materials, rubber diaphragm in the previous old machine on the split fixed saving energy consumption after the lack of problems, in the current latest product design rubber diaphragm eardrum more sufficient, in the same air volume and air source working conditions environment, The rubber diaphragm tympanic membrane is three times that of the polymer diaphragm tympanic membrane, which plays a lot of role in reducing the energy consumption of the entire machine. And another kind of polymer diaphragm in the industry full name polymer elastomer diaphragm, and the use of the diaphragm filter press is polymer elastomer diaphragm filter press, in general, most of the strong alkali and organic solvent filter material process used more, and the performance is more ideal, and the service life is also considerable, in accordance with different customers need to press components can be configured food grade and ordinary grade, in many equipment have PLC human-computer interface to operate, For ordinary materials, the diaphragm eardrum can fully play the role of pressing and dehydration in about 3-15 minutes, which can be described as twice the result with half the effort. From the perspective of the use of diaphragm filter press, we can see that the diaphragm filter press equipment has achieved a filtration public welfare of efficient dehydration compared with the same type of ordinary equipment, and can also guarantee its own filtration effect to a certain extent, greatly reducing the water content probability of its filter cake, reducing the moisture content of the filter cake while also reducing environmental pollution and reducing the surrounding labor and cost expenditure, saving certain expenses for the enterprise unit.

Waca liyaneKirim PitakonanPisah Sabuk Filter Press

The Split Belt Filter Press utamané dumadi saka piranti drive, pigura, penet roll, ndhuwur Filter sabuk, Filter ngisor sabuk, Filter sabuk tensioning piranti, Filter sabuk piranti cleaning, piranti discharge, sistem kontrol online, sistem kontrol electrical, etc. akeh rentengan industri ing China, konsentrasi produksi industri kurang, riset lan pangembangan kapasitas dhuwur-mburi produk kurang, tingkat teknologi Manufaktur industri penet sabuk Filter kurang, etc., lan impor lan ekspor perdagangan defisit ngembangaken. Sawetara taun sabanjuré bakal dadi wektu kejut-kacepetan dhuwur kanggo industri penet Filter sabuk, lan akibat langsung saka kejut-kacepetan dhuwur iki kanggo mimpin kanggo expansion saka gaya polarisasi ing camp account. Dikarepake manawa ora bakal akeh perusahaan sing bisa urip ing pasar ing sawetara taun sabanjure. Nanging osilasi kacepetan dhuwur saka industri penet sabuk sabuk bakal nggawa kesempatan gedhe, lan asil kejut bakal nggawe operasi pasar luwih rasional. Dalan kanggo lokalisasi listrik dhuwur banget "bumpy". Bagean dhasar wis dadi papan cendhak sing mbatesi pangembangan industri penet sabuk sabuk China nganti dhuwur, sajrone periode Rencana Lima Taun kaping rolas, pamrentah bakal terus nambah lokalisasi bagean peralatan dhuwur-mburi sabuk saringan penet, sawetara Enterprises kondhang uga wis ngadeg metu, produk wis digunakake digunakake ing pangayoman lingkungan, kotamadya, pertambangan, daya listrik, kimia, electronics, pangan, pharmaceutical, tekstil lan industri liyane.

Waca liyaneKirim PitakonanMesin Press Filter Sabuk

Proses dewatering saka Belt Filter Press Machine bisa dipérang dadi papat orane tumrap sekolah penting: pretreatment, dehidrasi gravitasi, wedge area prepressure dewatering lan penet dewatering, lan teknologi nggunakake mesin Filter peralatan anyar, program-kontrol otomatis Chamber Filter Press, Diaphragm Filter Press, Pencet Filter Dewatering Sludge Deep, Peralatan Perawatan Sludge Sewage Terpadu, Sistem Filtrasi Presisi Online lan produk filtrasi sing ramah lingkungan liyane kanthi rega sing cukup lan kinerja sing dipercaya.

Bagean konsentrasi sing kapisah nggampangake nyaring endapan aglomerasi, nambah kapasitas perawatan. Struktur prasaja, operasi prasaja lan pangopènan gampang. Desain rol cekung-cembung khusus, kapasitas pangolahan gedhe, isi kelembapan sing kurang. Sabuk saringan paten sing unggul, pamisahan filtrat kanthi cepet, peeling kue lendhut sing apik, lan sisa sludge sing sithik. Tingkat panangkepan sludge sing apik lan efisiensi dhuwur. stabilitas dhuwur lan kekiatan banget. Ora ana swara utawa geter. Konsumsi listrik sing sithik. Dibandhingake karo dehydrator endhot domestik lan malah dehydrator account Eropah lan Amérika liyane, dehydrator endhot luwih saka model liyane, prabédan utama iku kain Filter iki beda, amarga dehydrator endhot digawe saka telung beda tebih lan implantasi elektrostatik, punika non -teken kain Filter endhot, reresik jumlah paling saka peralatan.