English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Produk

- View as

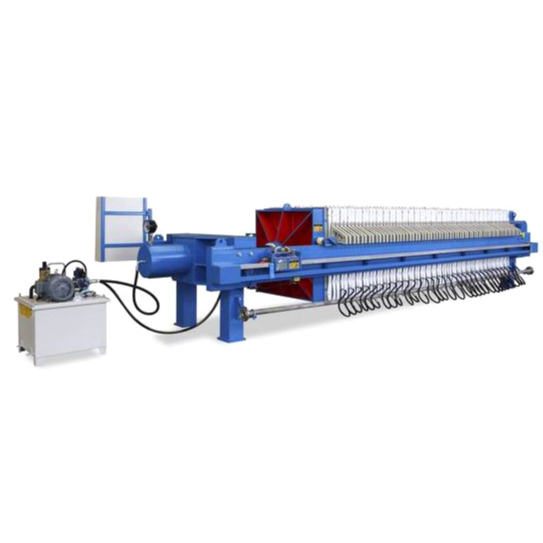

Plate Kothak Otomatis Hidrolik lan Filter Bingkai

The Hydraulic Automatic Box Plate And Frame Filter Press kasusun saka gantian piring Filter lan pigura Filter kanggo mbentuk klompok kamar Filter. Lumahing piring Filter wis grooves, lan bagean protruding digunakake kanggo ndhukung kain Filter. Pigura Filter lan piring Filter wis liwat bolongan ing sudhut lan mbentuk saluran lengkap kanggo akses menyang suspensi, wisuh banyu lan filtrate nalika nglumpuk. Ana gagang ing loro-lorone saka piring lan pigura kanggo ndhukung balok, lan piring lan pigura dipencet dening piranti mencet. Kain panyaring ing antarane piring lan pigura tumindak minangka gasket sealing. Tekanan hidrolik sing dilereni dilebokake menyang kamar panyaring dening pompa feed lan residu panyaring dibentuk ing kain panyaring nganti kamar panyaring diisi. Filtrat liwat kain Filter lan mili ing sadawane alur piring Filter menyang saluran sudhut pigura piring lan kosong dibuwang tengah. Sawise filtrasi, residu panyaring bisa dikumbah nganggo banyu cuci resik. Sawise ngumbah, hawa sing dikompres kadhangkala dilebokake kanggo mbusak cairan cuci sing isih ana. Banjur mbukak penet Filter kanggo mbusak turahan Filter, ngresiki kain Filter, re-pencet piring lan pigura, lan miwiti siklus apa sabanjuré.

Waca liyaneKirim PitakonanPiring Kothak Diafragma Hidrolik lan Filter Bingkai

Struktur Piring Kothak Diafragma Hidrolik lan Penyaring Bingkai beda-beda. Kamar Filter piring lan pigura Filter penet digawe saka rong jinis piring Filter staggered, piring Filter ngalangi lan piring Filter pigura. Pencet panyaring diafragma nggunakake rong piring panyaring sing beda, siji piring panyaring padat lan piring panyaring liyane. Piring Filter pigura kaya papat enclosures, lan piring Filter kothong wis matak dening rong lapisan, mbentuk longkangan gedhe ing tengah piring Filter, sing, piring Filter kothong.

Waca liyaneKirim PitakonanChamber Filter Press

The Chamber Filter Press kasusun saka piring Filter disusun ing balok utama ing urutan tartamtu, kain Filter sandwiched antarane piring Filter, lan piring Filter diaphragm, lan piring Filter, kain Filter lan piring Filter diaphragm disusun antarane saben. liyane, mbentuk sawetara Unit Filter sawijining - ing awal filtrasi kamar Filter, slurry lumebu saben kamar Filter liwat port feed ing piring tikaman ing push saka pump feed, lan disaring dening meksa kui dening pump feed.

Waca liyaneKirim PitakonanVertikal Filter Press Vertikal Filter Press

Vertikal Filter Press Vertikal Filter Press yaiku mesin filter otomatis sing bisa misahake barang padhet lan cairan kanthi efektif. Operasi utamane kalebu patang tahapan ing ngisor iki: filtrasi, ekstrusi diafragma, cuci kue, pangatusan udara.

Waca liyaneKirim PitakonanTekan Filter Diafragma

Pencet saringan diafragma yaiku penet saringan kanthi membran elastis sing dipasang ing antarane piring panyaring lan kain panyaring. Sajrone nggunakake, nalika dipakani wis rampung, cairan tekanan dhuwur utawa medium gas bisa nyuntikaken menyang piring diaphragm, lan banjur kabèh diaphragm bakal bulge lan pencet jajan Filter, lan banjur éling dehidrasi luwih saka jajan Filter, kang. umum dikenal minangka filtrasi pers.

Waca liyaneKirim PitakonanPolimer Elastomer Diaphragm Filter Press

Diaphragm filter press is a kind of filter press installed between the filter plate and the filter cloth with diaphragm equipment, as an important feature of the filter press accessories, its diaphragm due to the model, type of its diaphragm accessories material is also different, rubber diaphragm and polymer diaphragm Generally speaking, from the general category, diaphragm filter press diaphragm classification mainly includes polymer elastomer diaphragm and rubber diaphragm, which is the product of the current development in the past ten years, in the past materials are also different, as a rubber diaphragm, Rubber we all know its properties, in different types of rubber for different substances have different characteristics, usually rubber diaphragm filter press rubber diaphragm is mainly for weak alkali and weak acid filter materials will be more used, but can not be used for organic solvent filter materials, rubber diaphragm in the previous old machine on the split fixed saving energy consumption after the lack of problems, in the current latest product design rubber diaphragm eardrum more sufficient, in the same air volume and air source working conditions environment, The rubber diaphragm tympanic membrane is three times that of the polymer diaphragm tympanic membrane, which plays a lot of role in reducing the energy consumption of the entire machine. And another kind of polymer diaphragm in the industry full name polymer elastomer diaphragm, and the use of the diaphragm filter press is polymer elastomer diaphragm filter press, in general, most of the strong alkali and organic solvent filter material process used more, and the performance is more ideal, and the service life is also considerable, in accordance with different customers need to press components can be configured food grade and ordinary grade, in many equipment have PLC human-computer interface to operate, For ordinary materials, the diaphragm eardrum can fully play the role of pressing and dehydration in about 3-15 minutes, which can be described as twice the result with half the effort. From the perspective of the use of diaphragm filter press, we can see that the diaphragm filter press equipment has achieved a filtration public welfare of efficient dehydration compared with the same type of ordinary equipment, and can also guarantee its own filtration effect to a certain extent, greatly reducing the water content probability of its filter cake, reducing the moisture content of the filter cake while also reducing environmental pollution and reducing the surrounding labor and cost expenditure, saving certain expenses for the enterprise unit.

Waca liyaneKirim Pitakonan